HOTO Orbital Sander

The HOTO design redefines everyday tools with sleek aesthetics, intuitive interfaces, and smart functionality—enhancing usability and user confidence. Adding an orbital sander to the lineup would bring these values to surface finishing, blending performance with minimalist design for both pros and DIYers.

When comfort is ignored, fatigue follows.

Extended tool use often leads to wrist and hand strain, especially when grip and balance are overlooked. By improving ergonomics, comfort becomes an essential part of precision — not an afterthought. Designing for natural posture and reduced tension allows users to create with ease and endurance.

The right pressure defines the quality of every surface.

Too much pressure, and surfaces suffer; too little, and progress stalls. Integrating smart sensing technology can create real-time awareness of how users interact, improving sanding results. When data informs motion, accuracy becomes intuitive.

INTERVIEWS

I interviewed two industry professionals: Ben Jones, Director of the UC 1819 Makerspace, and Hayes Shanesy, a cabinet maker. Ben offered insights on tool use across skill levels from a teaching perspective, while Hayes provided practical input from daily professional use—together offering a well-rounded view of user needs.

BEN JONES

As an educator, he has a different view of power tools, focusing on how beginners without experience would use them. Finds that orbital sanders are used regularly, and users put to much pressure on the sander.

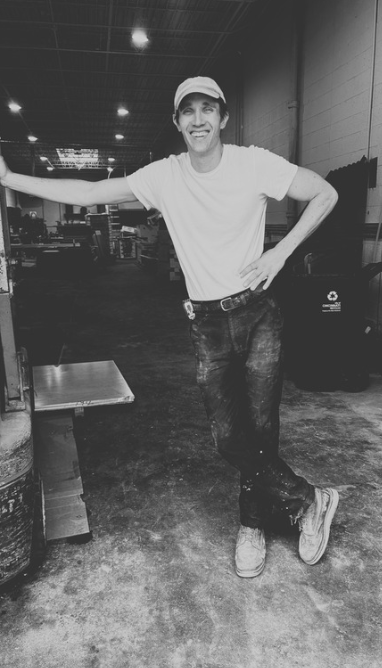

HAYES SHANESY

He embraces an artisanal aesthetic, valuing the craftsmanship of handmade furniture and goods. He uses various orbital sanders depending on the task, each offering its own advantages and drawbacks.

BEN JONES

HAYES SHANESY

ORBITAL SANDER CURRENT DRAWBACKS

POOR ERGONOMICS DESIGN AND USER FATIGUE

Many orbital sanders have bulky or poorly contoured grips, leading to discomfort and hand fatigue during extended use. A lack of vibration control can also contribute to strain on the user’s wrist and arm.

INSUFFICENT DUST COLLECTION

Standard orbital sanders often have weak or poorly sealed dust collection systems, resulting in debris escaping into the work area. This not only creates a mess but can also pose health and visibility issues during sanding.

LACK OF PRESSURE FEEDBACK OR CONTROL

Traditional models offer no feedback on the amount of pressure being applied. Excessive pressure can damage surfaces or reduce the tool’s efficiency, while too little pressure may not achieve the desired sanding results—yet users often have to rely on guesswork.

Visited the team at Edward B. Mueller Company, a Cincinnati-based dealer of new and used woodworking machinery, to discuss their top-line Festool orbital sanders and explore potential areas for improvement and explore ergonomics, human factors, and affordance.

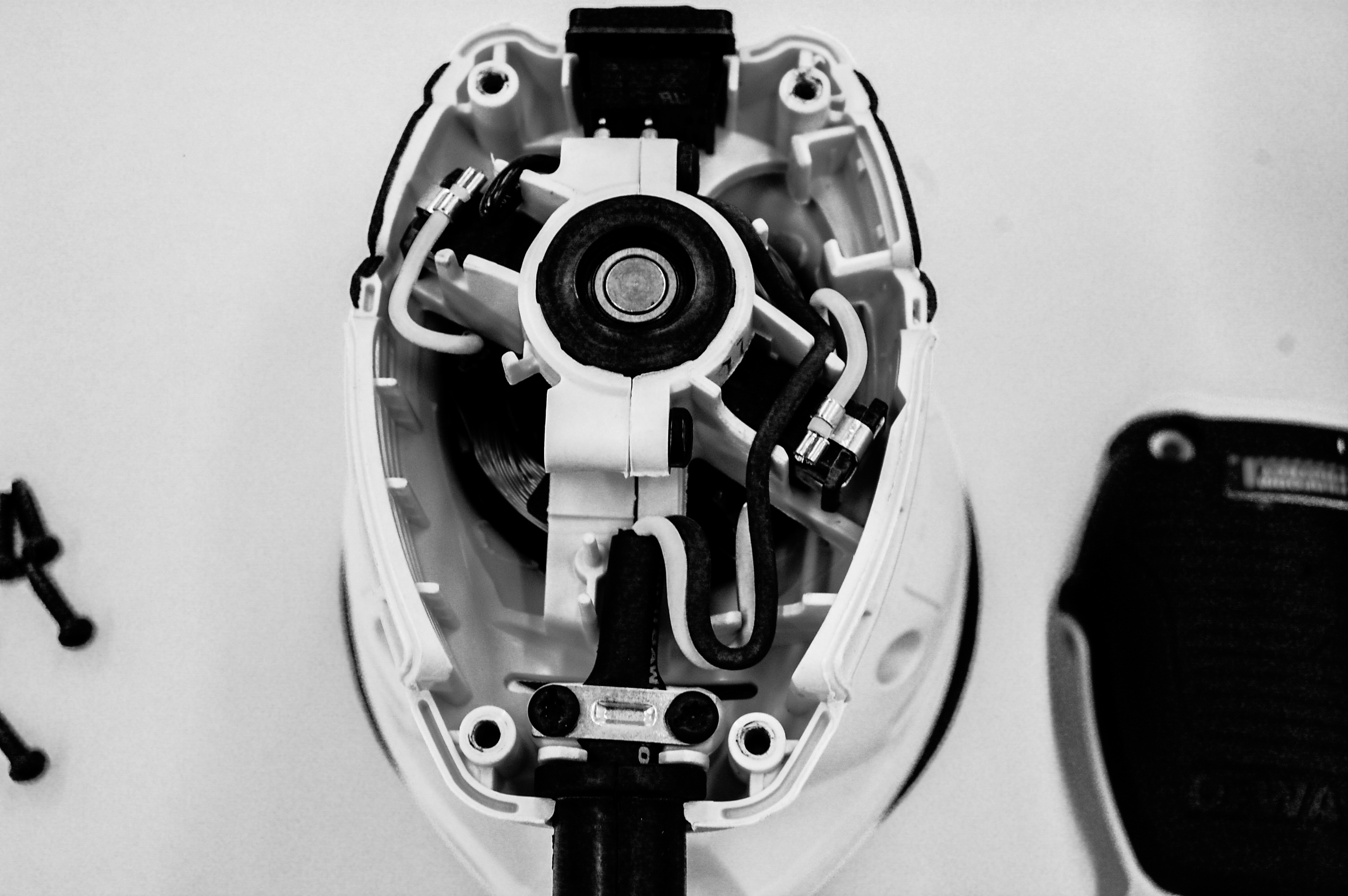

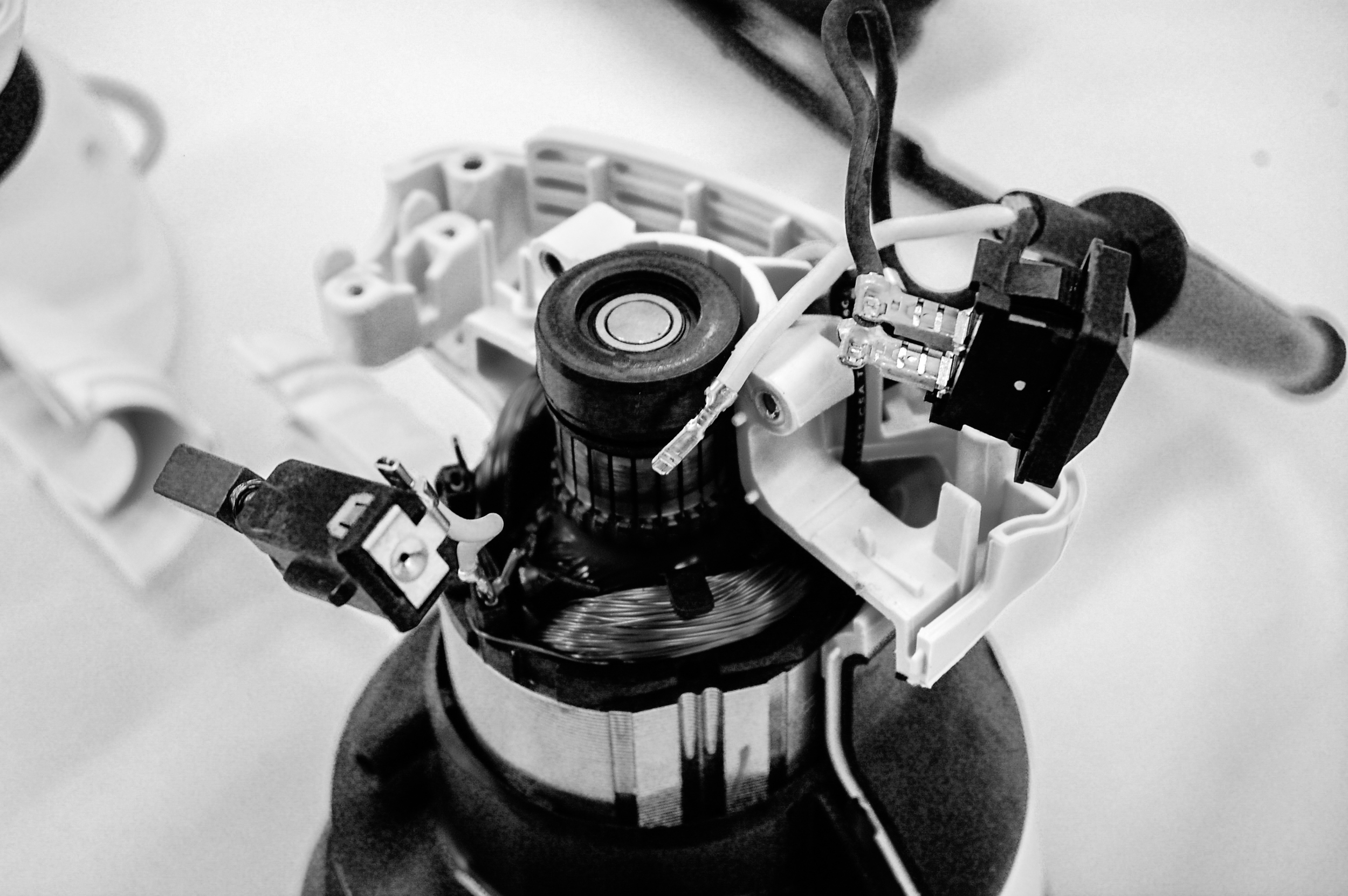

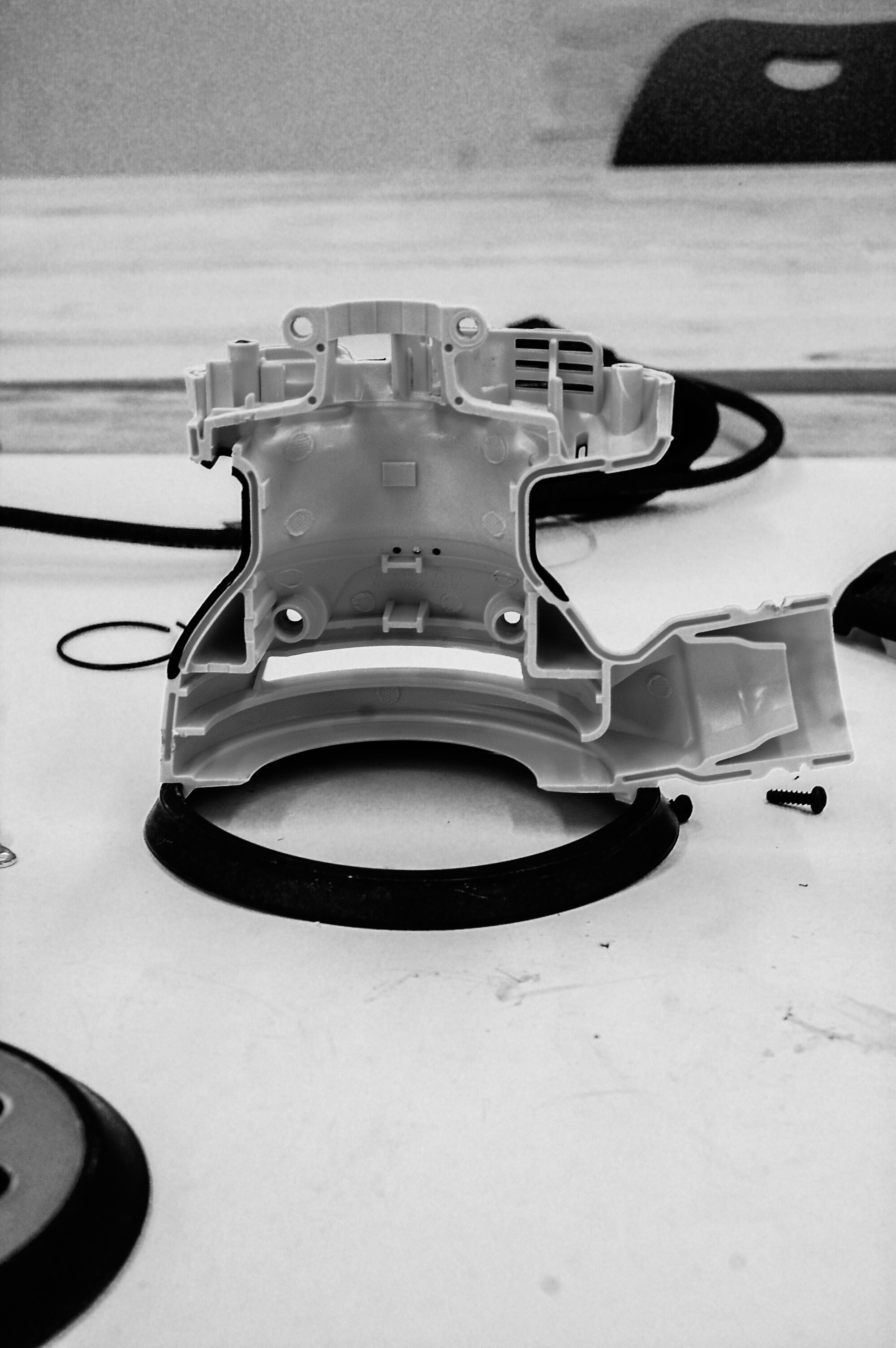

tool tare down

Taking apart an orbital sander helps inform the design process by revealing how its internal components function and fit together, offering valuable insight into ergonomics, construction, and opportunities for innovation.

brand involvement

HOTO “WE MAKE COOL TOOLS”

HOTO is a modern, design-driven tool brand that blends minimalist aesthetics with smart technology, creating sleek, user-friendly products that appeal to young homeowners, DIY enthusiasts, and design-conscious users looking for intuitive, stylish tools that fit seamlessly into their lifestyle.

SIMPLE ERGONOMICS

HOTO emphasizes smooth, continuous curves and a lack of exposed screws or harsh edges, creating products that are both ergonomic and visually refined.

INTEGRATED TECHNOLOGY AND LED SCREENS

Many HOTO products incorporate minimalist LED or OLED screens that provide real-time feedback, combining functionality with a sleek, futuristic interface.

DURABLE LIGHTWEIGHT MATERIALS

HOTO uses high-quality plastics and aluminum alloys to create tools that are sturdy enough for everyday tasks but light enough for comfortable, prolonged use.

DESIGN GOALS

ERGONOMIC COMFORT

Ergonomic, intuitive grip and handle that supports prolonged use—while maintaining HOTO’s signature clean lines and modern design language.

SMART DIGITAL INTEGRATION

Incorporate a simple display to show speed settings, and real-time pressure feedback—giving users greater control and awareness without adding visual clutter

SEAMLESS DUST MANAGEMENT

Design an integrated, efficient dust collection system with a magnetic or twist-lock canister and clear visual indicators.

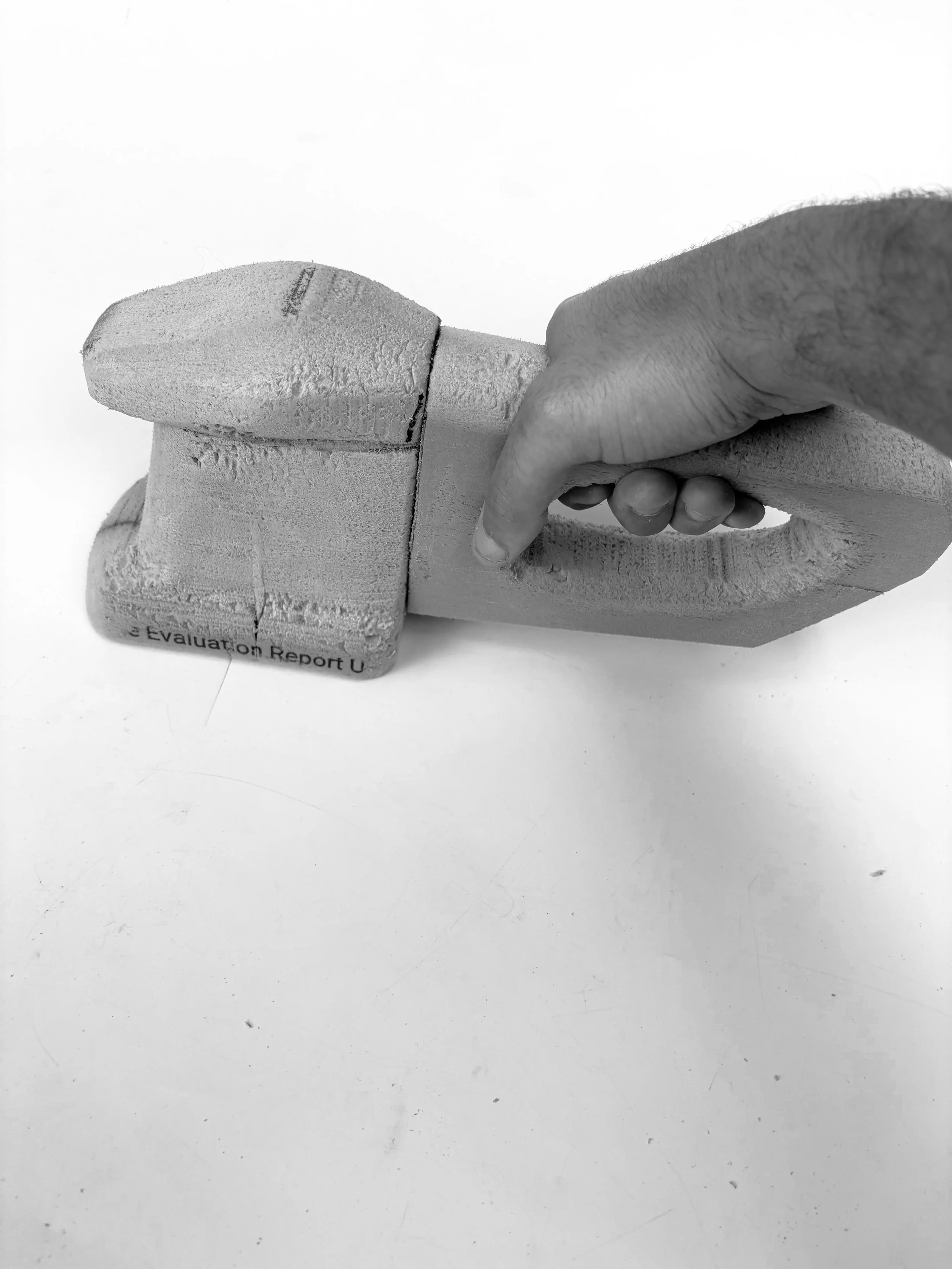

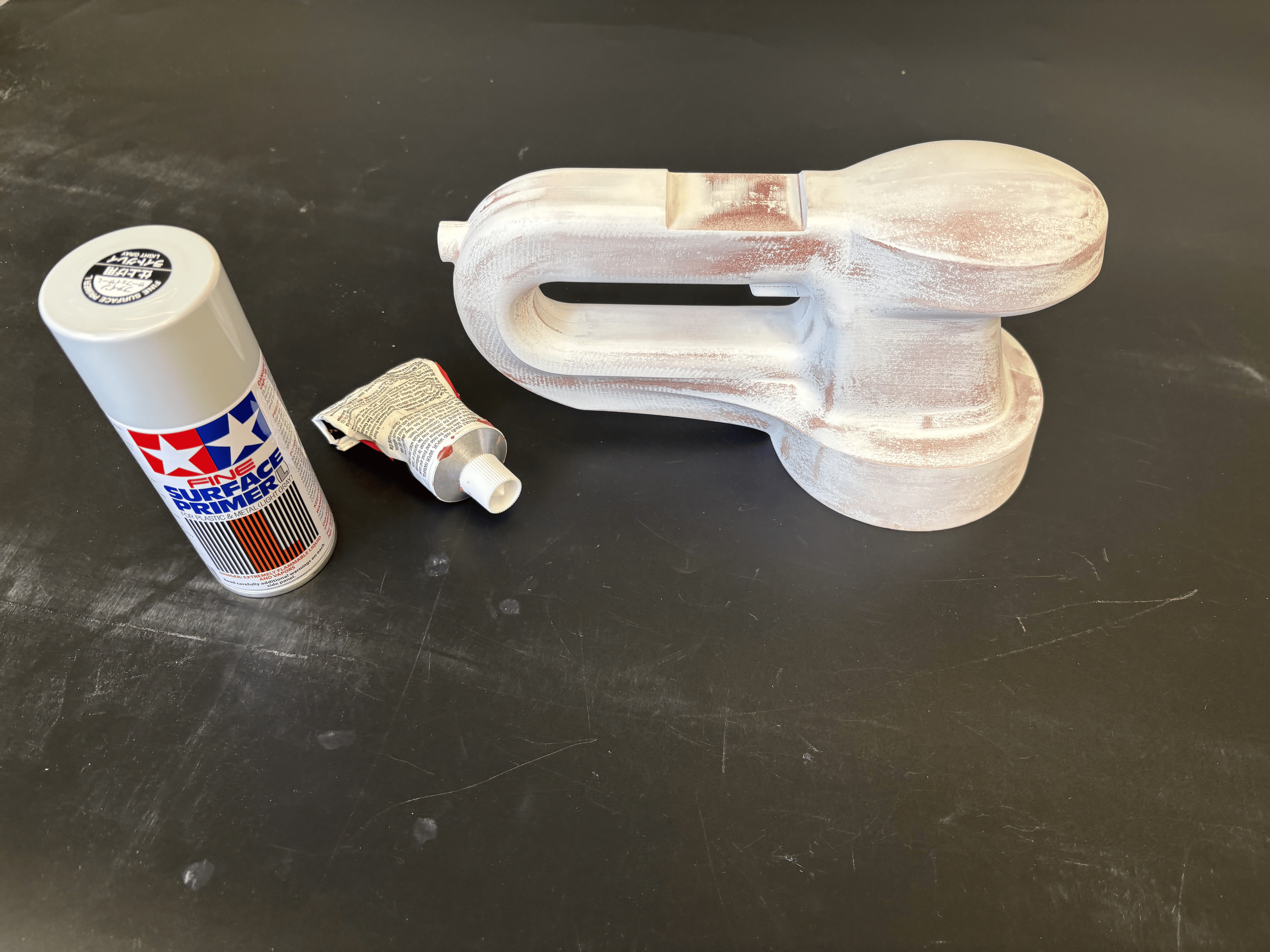

Model making

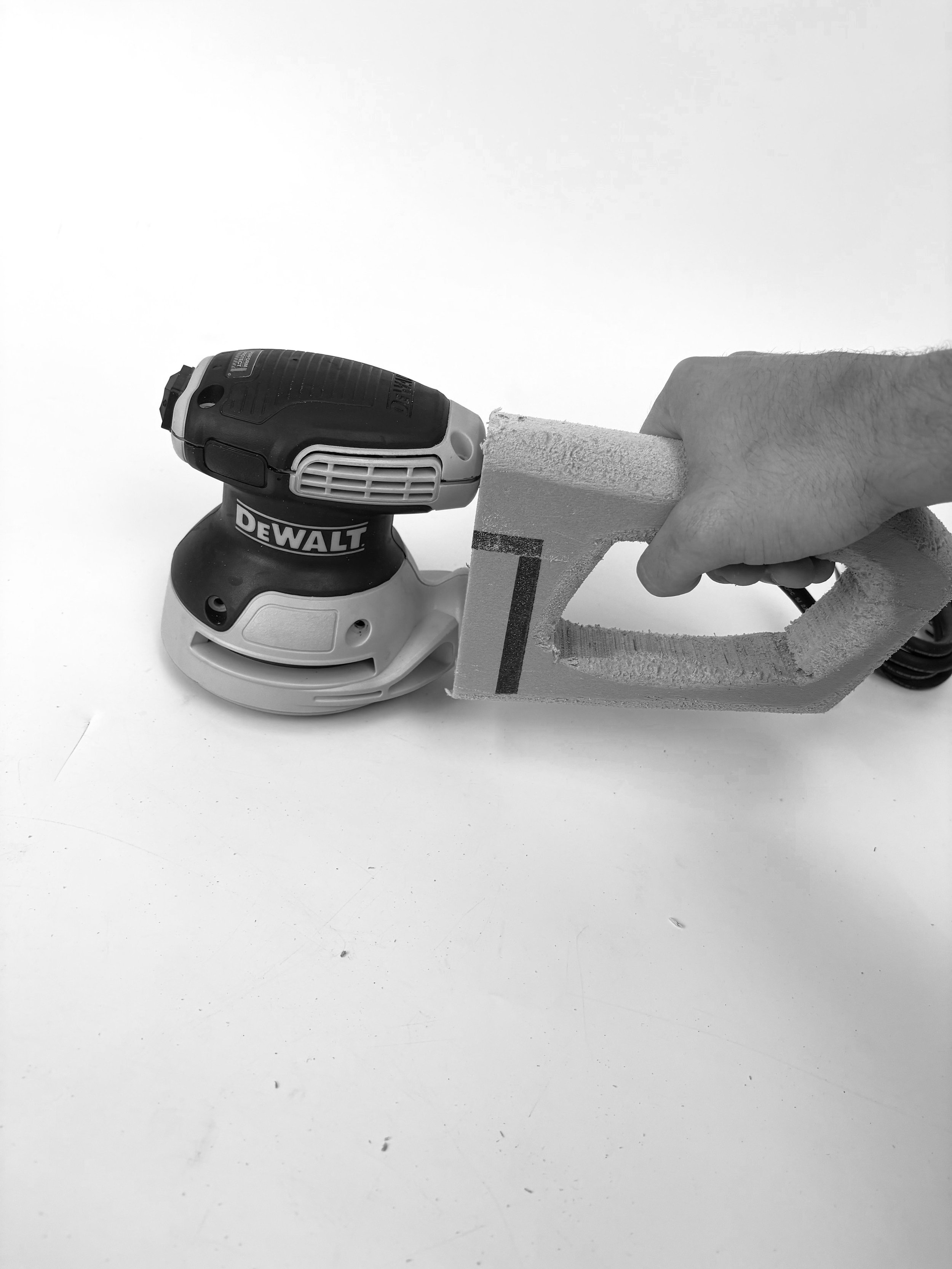

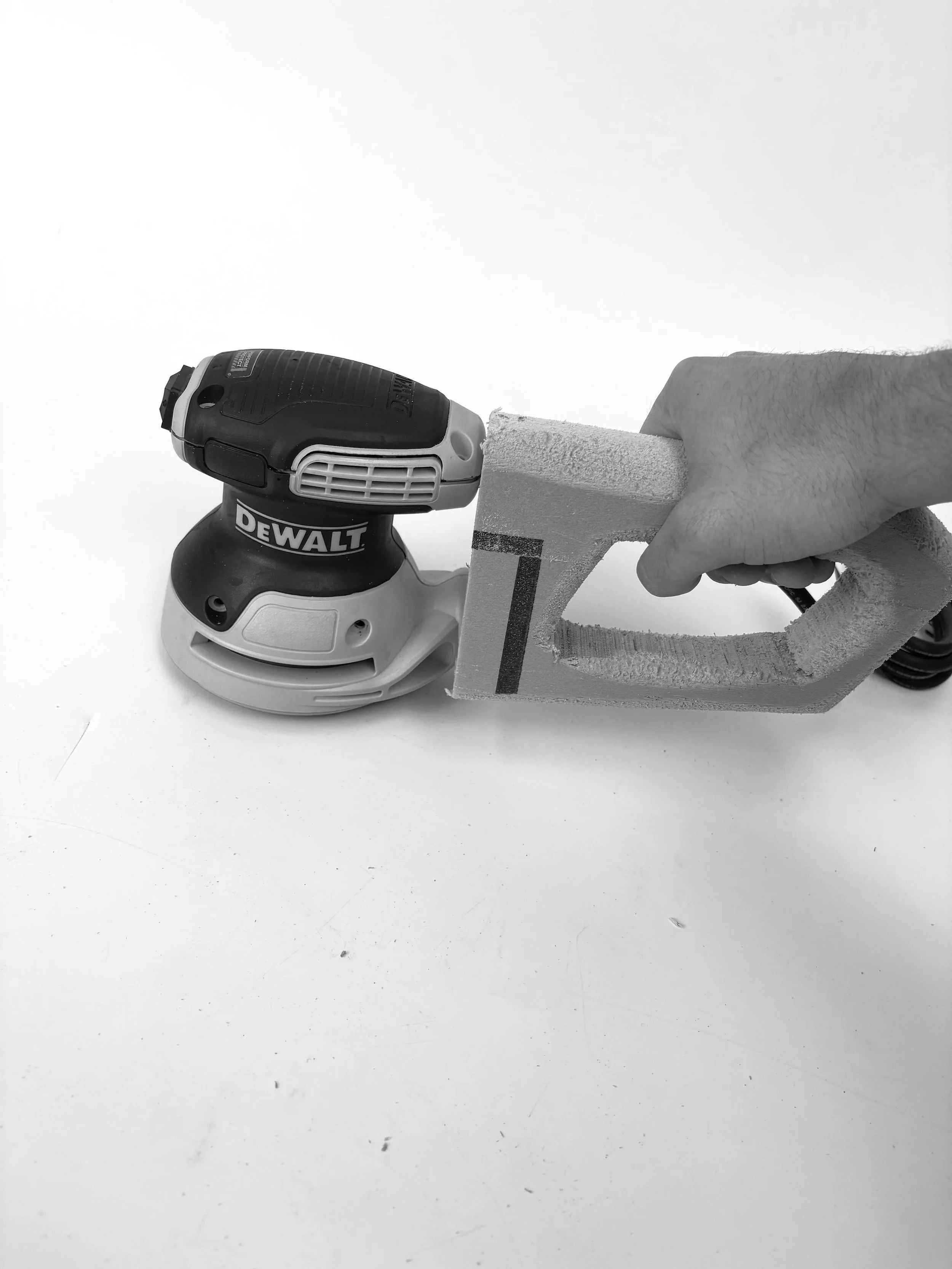

PAlm grip form ideation

Creating foam models of palm grips allows for quick, hands-on testing of ergonomics, helping refine the comfort, shape, and usability of the orbital sander early in the design process.

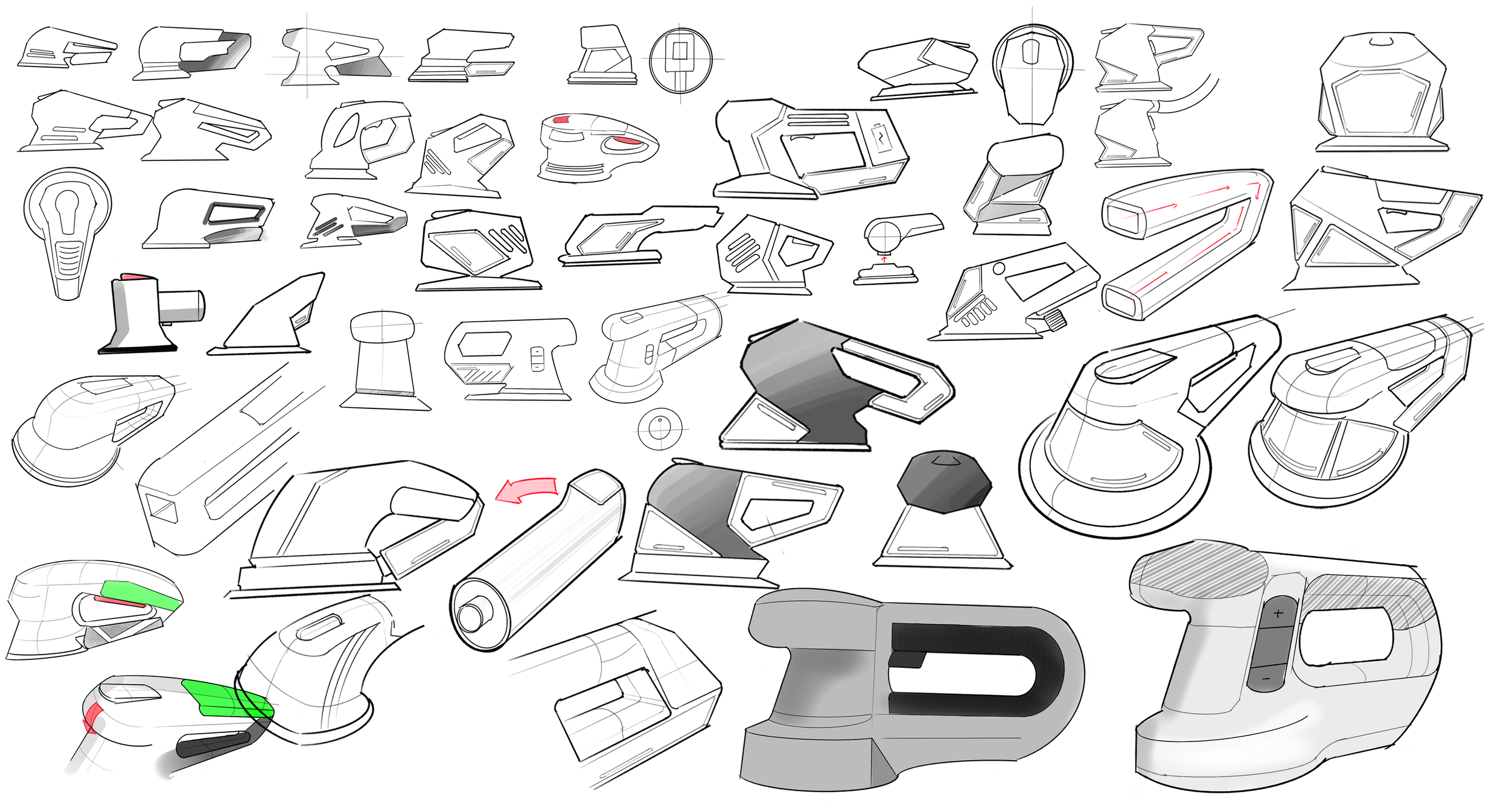

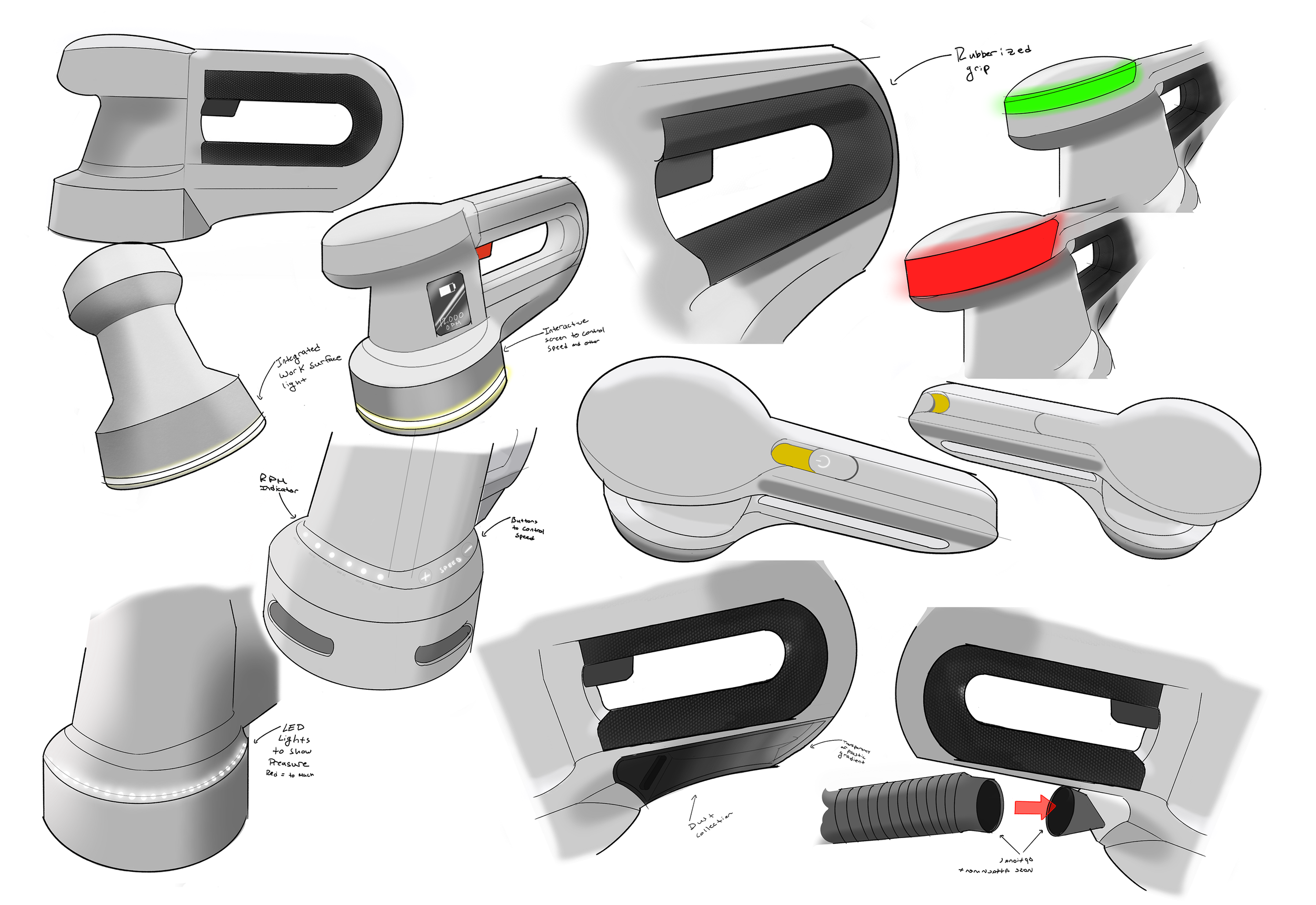

full FORM IDEATION

Combining the best features of rear handles and palm grips onto various bases using quick 3D-printed Blender models to explore ergonomic and functional possibilities

REAR HANDle FORM IDEATION

Building foam models of the rear handle helped me explore form, fit, and hand positioning while also testing trigger placement, allowing for quick adjustments to improve overall comfort and control.

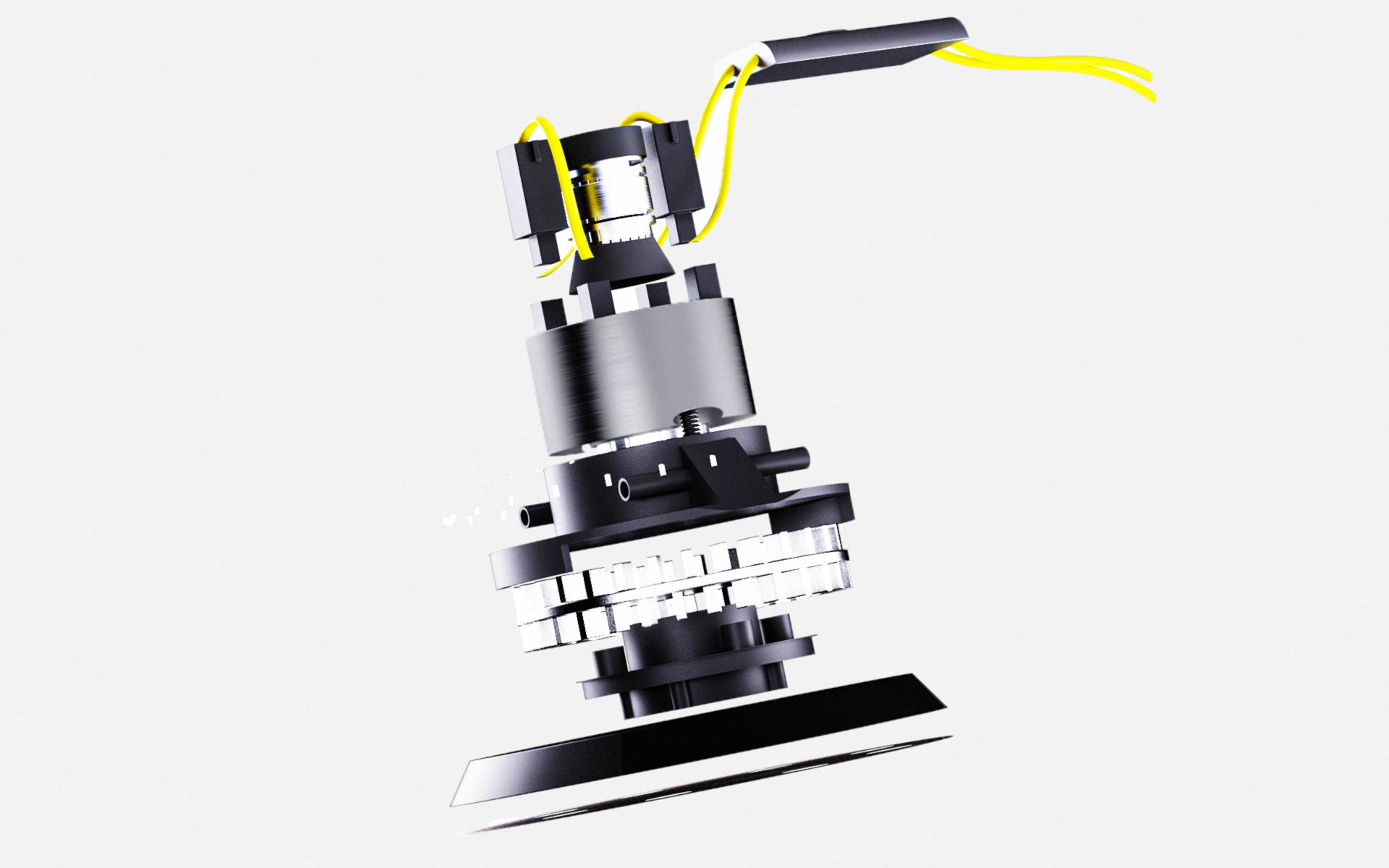

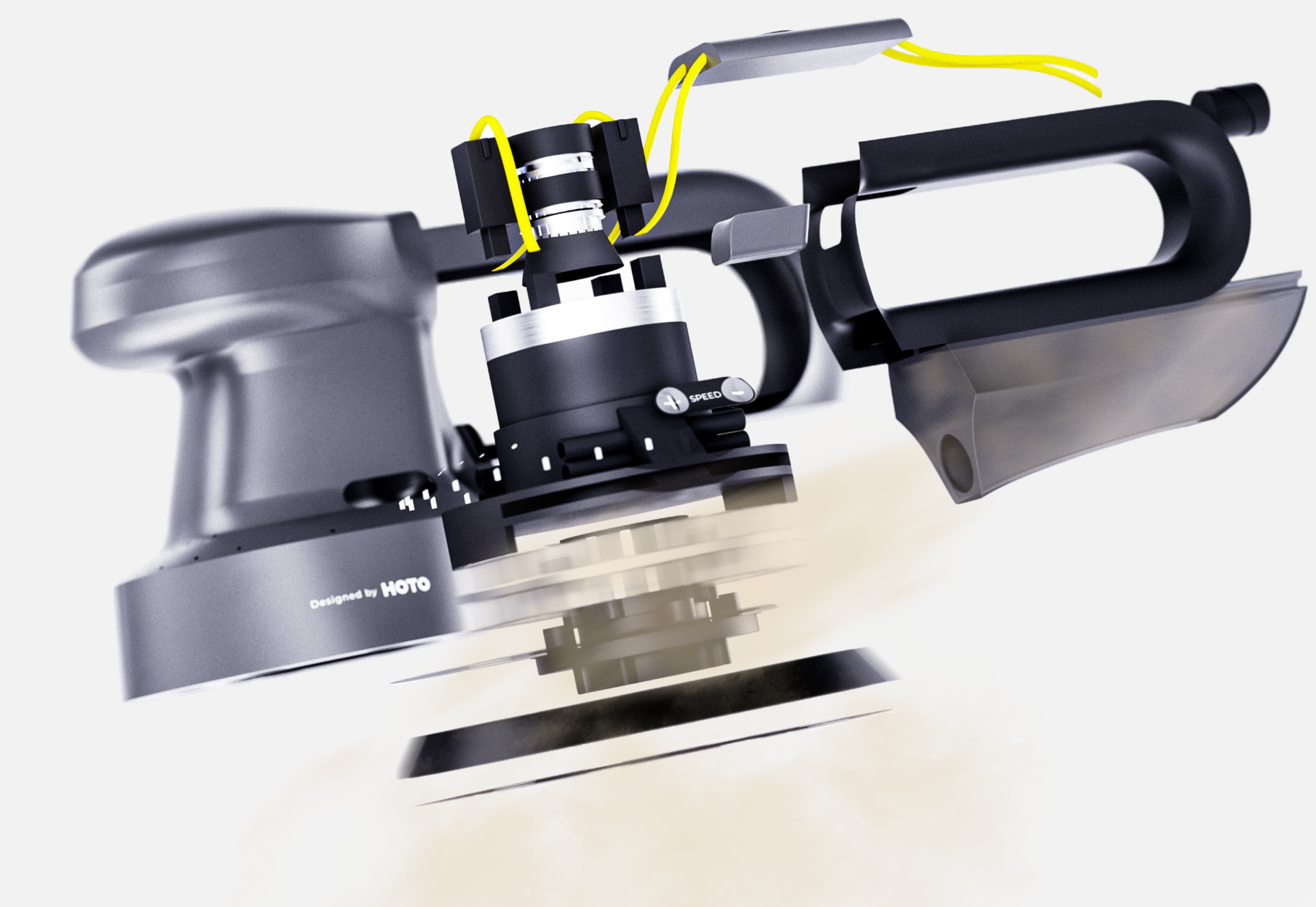

Internals

3D-modeled and replicated the internal components of the orbital sander for the tool tear down. Accurately rebuilding the existing sanding mechanism allowed me to design around a proven, fully functional system—following a “form follows function” approach.

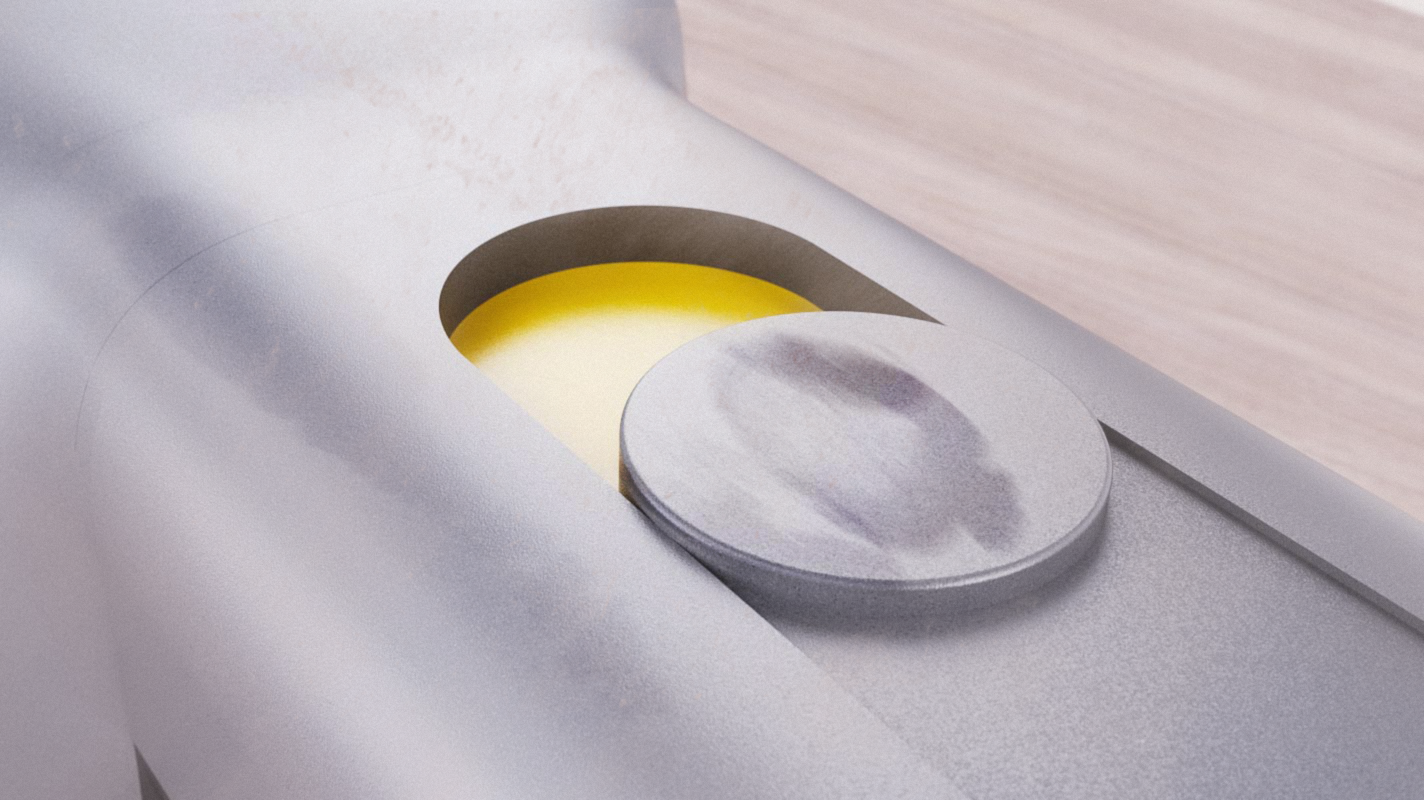

External 3d modeling

Used Fusion 360 surface modeling to build the form, referencing a previous quick model. Imported into KeyShot to check surface tangency and ensure smooth transitions.

hoto tech integration ideation

After creating final form, Ideating ways to match the features to integrate with HOTO’s signature design language—where technology is seamlessly embedded in a minimalist and intuitive form. Focusing on how HOTO balances smart functionality with clean, simplified aesthetics.

Detachable Dust Collection System

Power Switch

Integrated Tech and dust collection

Most orbital sanders lack user-friendly features that improve sanding quality. Adding smart speed control, pressure feedback, and an efficient dust-collection system solves common issues like inconsistency and mess. A streamlined, clear hard-plastic dust collector provides cleaner, more reliable results than traditional cloth bags.

Preset Speed Controls

Speed Control Trigger

Final Model Making

Produced the final form by CNC-machining high-density machinable foam, followed by surface refinement and a uniform gray primer finish.